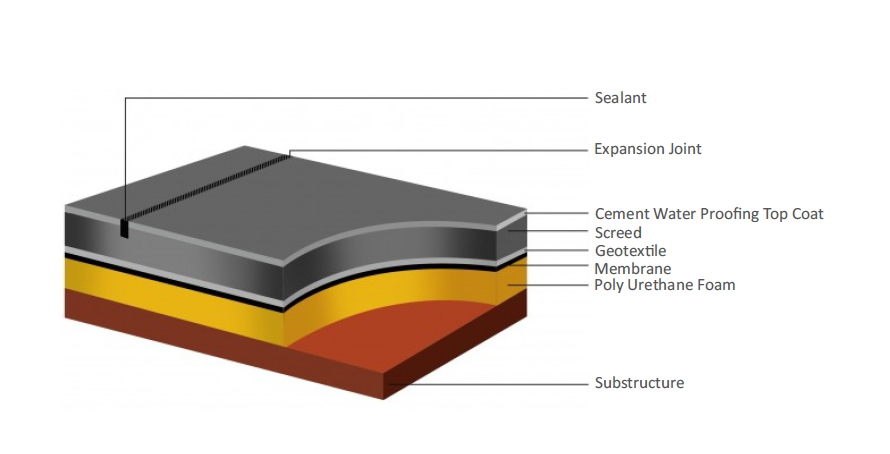

Waterproofing and Combo System

Why Combo Roof System?

Combo Roof system is a comprehensive system comprising of waterproofing, thermal insulation and finishing for the roof. This unique system is a technically advanced fast curing. Dubai Central Laboratory (DCL) Certified PU Foam system which forms joint free water proofing and thermal insulation is fully bonded to the roof slab. This system provides a manufacturer’s Guarantee of 25 years against any leakage.

The system meets all latest thermal insulation standards and regulations in UAE and is accepted by all major property developers, consultants and contractors. The system is also approved by various authorities like Dubai Municipality, Sharjah Municipality, Sharjah Water and Electricity authority; Combo Roof system is an assured solution for your roof.

Benefits of Combo Roof System

Joint free insulation & waterproofing with 25 years manufacturers Guarantee

Load Bearing Capacity up to 2½ tons per square meter

Single submittal & approval for the entire system

Roof tiles not required

Fully mechanized time saving installation procedures

Ability & capacity to undertake fast track projects

Easy repair & maintenance

Multilayer Waterproofing

Lower electricity consumption due to better insulation

Thermal shock resistant roof

Guaranteed Waterproofing

Products and their performance do not matter alone when it comes to waterproofing, the application has utmost importance. This is why Combo system is installed by us to assure the highest performance of all system elements. It starts with the spray application of the 2-component PU foam to assure 100% bonding to the substrate and ends with the application of the final liquid applied final coating. We undertake installation and ensure quality of the applied method.

Application Procedure

Site Preparation:

Upon casting and complete curing of roof slab, our engineer shall visit the site to inspect the roof and accept the roof for waterproofing and heat insulation works. A preliminary site inspection shall be carried out and any further preparation work if required shall be brought to the attention of the main contractor.

PU Application:

Upon completion of cleaning, spray application of the 1st layer shall commence where a combination of Polyol & MDI is sprayed onto the roof slab including up stands using combination equipment. The spray applied foam in liquid state hits the slab at a high pressure and penetrates into every crack and pin holes that exist on the slab. In minute it expands 30 times its volume and solidifies thereby sealing the entire substrate. The foam creates an impermeable waterproofing and insulation layer with high thermal resistance, closing all pores and cracks that exists in the roof slab.

UV Protection Coating:

On completion of polyurethane foam application, POLY TEX acrylic liquid UV protection coating shall be applied over entire foam to protect it from UV rays till the water test procedure is completed.

Flood Testing the Roof:

Once acrylic UV coating is completely dried (minimum 24 hours), Our Engineer will visit the site to inspect the works completed and give clearance for flood test (minimum 24 hours), On successful completion of flood test a test report shall be prepared and maintained for records.

Paneling and Screed Laying:

Upon successful completion of flood test, water shall be removed and POLYFAB geo-textile (120gsm) membrane shall be laid as a protection layer over the entire roof area and our team will do the paneling work using POLYBOARD expansion joint filler board and pre-mixed cementitious adhesive mortar to attain the desired slope levels prior to commencement of screeding works.

Protective screed of 300 OPC 10 mm aggregate, 25 N/mm2 strength screed will be laid in panels. Minimum thickness of the screed will be 45 mm and average thickness will be 80 mm. The screed will be finished manually by our trained masons and cured as per standard procedures. The screed is added with plasticizers and micro fibers to avoid crack.

Angle Fillets and Joint Treatments:

Angle fillets are done after application of POLY BOND PVA bonding agent to the corners of size 100×100 mm. Once screed is completely cured, all construction joints shall be opened and treated using heavy duty POLY SEAL 1 PU Polyurethane sealant and backing rod for accommodating movement of the concrete during expansion and contraction.

Finishing:

Once the applied sealant is completely cured, POLYFLEX – COMBO acrylic cementitious coating shall be applied over entire screed including upstands to form a uniform coating of maximum thickness 1000 microns. This coating provide aesthetic look to the roof.

Our Services

Get In Touch

P.O. Box 3630 Ras Al Khaimah

United Arab Emirates

+ 971 7 2222913

+ 971 7 2222914

info@regency-house.com

www.regency-house.com